SolarTrak®

Development Milestones

Page

8 - Daylighting Systems

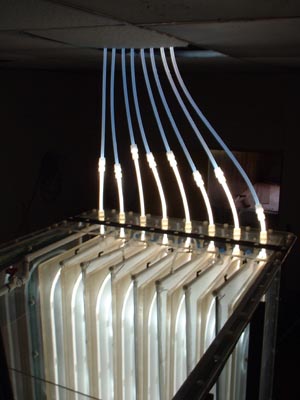

This Cassegrain parabolic dish concentrator energizes eight 1/2" diameter fiber-optic strands to 11000 lumens each. The fiber is then routed through the ceiling (roof) of the building and terminates on the Bio-Reactor plates shown below.

This prototype was designed at Oak Ridge National Laboratories in Tennessee and is installed on the roof of a lab at Ohio University for a joint test of the fiber-optic lighting and the reactor.

The ultimate use for the system will be for room daylighting where the fiber is combined with special florescent lights that can operate on a computerized dimmer.

When depending on the natural sunlight for reading or any circumstance where one expects unwavering light, it is disconcerting to have the light in the room go out every time a cloud moves in front of the Sun. In this system, a computer monitors the natural light level and 'brings up' the florescent light as the natural illumination fades; lowering it when the Sun again becomes visible.

Seen in a double reflection are three of the eight fiber receivers. A 3/8" spot of about 1150 suns is focused on the end of a piece of quartz rod after passing through a spectral filter where it begins its travels to become 'the light at the end of the tunnel'. The segmented secondary reflector (seen as a reflection in the primary dish) consists of eight trapezoid mirrors that takes the partially focused light from the primary reflector and finishes it down to 3/8" while reversing the beam backwards so the fiber can exit the back of the array.

The fibers exit separately through the back of the dish and are then brought together and directed down the center of the mounting post, into the ceiling and down to the eight reactor illumination plates.

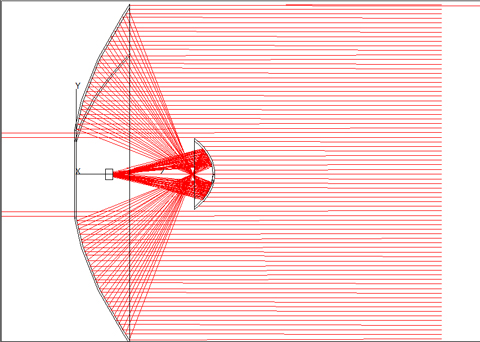

This figure shows the path of the focused light to discreet points where the quartz rods receive the light and transmit it into the plastic fiber.

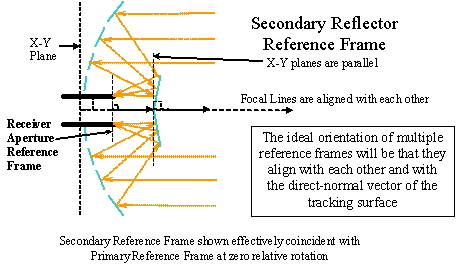

This next generation fiberoptic collector, also a Cassegrain configuration uses a single ellipsoidal secondary reflector to redirect all of the light from the primary parabolic dsih mirror to a single point where a bundle of fiber conduits receive the light and transmit it on. The elliptical secondary also performs the IR filtering function such that the heat transmitted down the fiber is reduced by as much as 60% though as seen in the picture below-right, there is still sufficient heat to burn a piece of wood after only a few seconds.

Note in the following illustration that the light focused by the parabolic primary reflector actually passes through its focal point before being redirected by the secondary mirror. This combination if parabolic and ellipsoid reflectors produces an extremely tight beam that can enter the quartz rod with such a small angle of incidence that very little of the light is reflected off of the receiver surface. The receiver, a combination of quartz rod and the downstream bundle of plastic fiber are mounted from the back of the mirror unit and protrude throught the hole in the middle of the parabolic dish. No light is lost to the hole because the secondary mirror exactly covers that opening anyway.